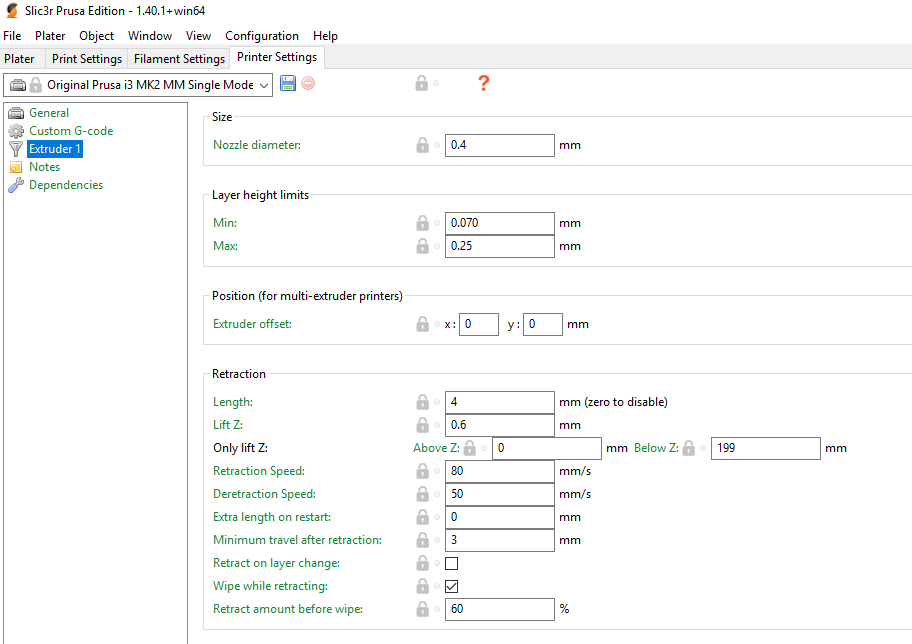

Retraction – Start with 3 mm at 20 mm/s, then look to shorten the distance, if possible.You may even want to slow down to 10 mm/s for the first layer if you’re having adhesion issues. Print Speed – 25-30 mm/s is a good range as TPU performs best at slower print speeds on the Ender 3.

Prusa slicer tpu settings full#

Read our full review: Creality Ender 3 S1 Pro hands-on review Recommended Slicer Settings for Printing TPU with Ender 3

The result is that the Ender 3 S1 has a far easier time printing TPU than on previous Ender 3 printers.Įnder 3 S1 Pro is available for $479 - Available at Creality store here Not only is the filament path vastly shorter, reducing the chances of bending and clogging, but the dual gears provide additional traction and pressure-feeds TPU into the extruder more smoothly. The direct drive system forgoes the lengthy Bowden tubing entirely, mounting the stepper motor and gears onto the print head. The Ender 3 S1 largely sidesteps most TPU issues because the printer has a ‘Sprite’ full-metal dual-gear direct drive extruder. Retraction – 1 mm at 60 mm/s offers a great starting point with a balance of distance and speed adapted to the S1’s direct drive extruder.Though the Ender 3 S1 and Ender 3 S1 Pro have an easier time taming TPU, a slower print speed always improves part and model quality. Here’s what I recommend when printing TPU on the Ender 3 S1 and Ender S1 Pro: This isn’t an issue for fairly stiff filaments like PLA and ABS, but can cause flexibles like TPU to bend and jam/clog in the extruder or tubing due to their rubber-like properties.ĭue to the long filament path between the motor and hot end in the Bowden system, there can also be minor delays in printing processes such as retraction, leading to problems like stringing.įortunately, there are ways to mitigate these issues, reducing them to a sporadic occurrence rather than a guaranteed headache every time you try to print TPU on the Ender 3.

TPU filament with stringing print issues. In a Bowden system, the stepper motor sits on the frame rather than the print head, feeding filament through a long Bowden tube made of PTFE plastic to the print head for melting and printing onto the bed. This is mainly down to these three models employing a Bowden extruder. However, due to the way the Ender 3, Pro, and V2 are designed, producing quality prints can be quite a struggle. In theory, the Ender 3 is equipped to print TPU, checking off all the specification criteria, chiefly a max extruder temperature of 255☌, well above the 210☌-230☌ required to print the filament. When you buy through links on our site, we may earn an affiliate commission.

0 kommentar(er)

0 kommentar(er)